Machining with the highest precision

Turned parts order online and have them manufactured

CNC turned parts easy to order online. Fast service with attractive prices. You will receive a free test certificate with every order. Upload CAD file and receive quote within 48 hours

1.000

Satisfied customers

5.500

Available machines

0,017%

Complaint rate

What distinguishes our CNC turned parts?

Part of our self-image is the continuous investment in our machinery. This is the only way we can guarantee the quality and precision in contract manufacturing for which our customers appreciate us. In the field of CNC turning (Computerized Numeric Control), we rely on automatic lathes and sliding headstock lathes. CNC long turned parts and precision turned parts on our CNC machines can be processed from 3 – 600 mm workpiece diameter and a maximum length of 2000 mm.

For the production of individual parts or repair work in CNC turning, we also have conventional CNC lathes and automatic lathes with which we can machine turned parts up to a diameter of 400 mm and a maximum length of 1000 mm.

Special advantages of CNC turning processes at CNC24

As soon as our non-binding offer is acceptable to you and we receive the order from you, your turned parts will immediately go into production. Depending on the requirements and the task, our CNC machines or the corresponding conventional variant are used. Our team is very familiar with both common CNC controls and the operation of manual lathes – so that your individual parts or series production will always be machined by the appropriate experts at our company.

In contract manufacturing, we take on your orders from a batch size of 1 piece – upwards there are virtually no limits. Assembly production is also part of our area of expertise. Since, in addition to lathes, we also have several milling machines and a sheet metal working department, we can offer you the ready-to-install production and assembly of even the most complex workpieces and components.

Made in Germany at an extremely competitive price, because we rely not only on rational production but also on the latest management software – and thus keep our ancillary costs as low as possible!

Get a quote for your parts

We will send you a suitable offer within 48 hours

Perfect components in just 3 steps!

1

Make a request

Upload production drawing and specify order. You will receive your offer within 48 hours.

2

Quality control

We find the right paver, supervise production and take care of quality control in our in-house measuring center.

3

Components received

You receive your quality-tested components including detailed test certificate.

Why CNC24

Your advantages

- Flexible and free capacities at any time

- Attractive prices for all components

- Quality control according to ISO 9001:2015

- One contract and contact person for all manufacturing processes

- Digital processes with personal contact person

- Global Supply Chain with German Quality Standards 🇩🇪

You have the choice

Our delivery times

- Offer within 48 hours

- Standard production in 15-20 working days

- Express service in 6-12 working days

Get a quote for your parts

We will send you a suitable offer within 48 hours

Turned part production

How are CNC turned parts manufactured?

As soon as you accept our non-binding quote based on the submitted drawings and we receive the order from you, your turned parts will immediately go into production. Depending on the requirements and the task, our CNC machines or the corresponding conventional variant are used as manufacturing processes. Our team is very familiar with both common CNC controls and the operation of manual lathes – so that your individual parts or series production will always be processed by the appropriate experts at our company.

In contract manufacturing, we take on your orders from a batch size of 1 piece – upwards there are virtually no limits. We are not a B2B marketplace, but work with a selected partner network. Thus, every turned parts manufacturer is audited by us on a regular basis. Our quality management is DIN ISO 9001:2015 (DIN EN ISO) certified.

Material selection

Which materials are suitable for turning?

In addition to the „classic“ materials of machining such as steel, stainless steel, free-cutting steel or aluminum, our range of services naturally also includes the machining of materials such as copper, brass or plastics. Of course, we can also machine special materials for you, such as high-alloy steels, by arrangement.

Of course, our expertise does not end with the turning of workpieces: We will be happy to take on further assembly services or the coating of finished assemblies for you.

Just talk to us about our possibilities – we are already looking forward to your call!

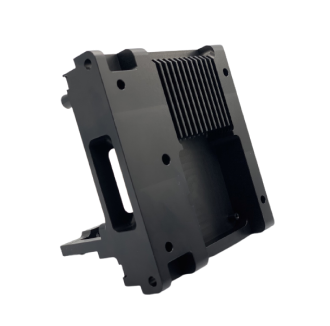

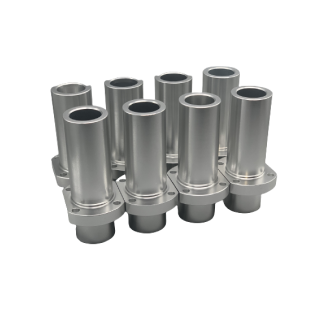

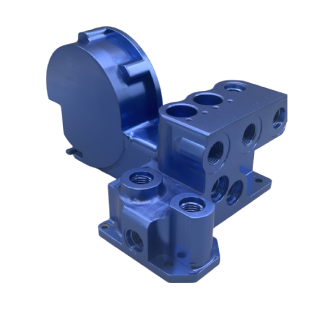

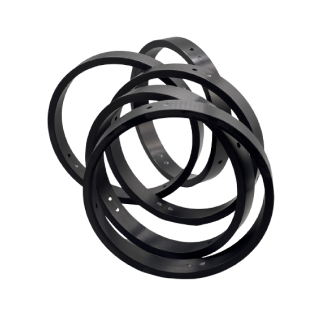

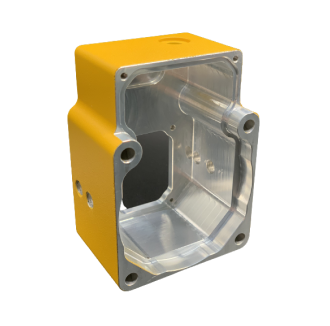

What we produce

Sample components

CNC turning process: All work steps at a glance

Preparation

1. prepare semi-finished products

Cutting processes such as sawing, laser cutting, flame cutting or waterjet cutting are used to prepare the turned material – the semi-finished products.

Setup time

2. set up machine

In order to prepare the machine tool for the production of the turned part, all necessary semi-finished products as well as turning and milling tools are clamped. Experienced and highly qualified employees speed up the process.

Programming

3. CNC programming

The machining program (NC program) tells the CNC machine how to use the tools to create the finished part from the semi-finished product. With modern computer-controlled system infrastructure, programming is done with CAM software.

Manufacturing

4. manufacture turned part

After preparation, the actual CNC machining takes place in main and secondary steps. Main steps, such as cutting the material, sometimes require more time. Non-productive times, such as for tool changes on CNC lathes, must be kept short.

CNC24 is the leading portal for CNC manufacturing in Europe

CNC24 simplifies the procurement of CNC turned and milled parts.

CNC24 is your specialist and contact for prototypes, single parts, small series as well as for higher quantities. Our know-how in CNC turning and CNC milling, our own experience in manufacturing, a Europe-wide network of partners and the CNC24 quality management according to DIN EN ISO 9001:2015 make us your competent partner.

CNC24

The easiest way to order components