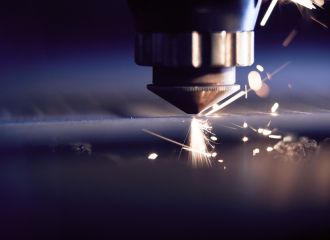

Sheet metal working with the highest precision

Laser cutting

Order laser parts online with the highest precision. Sheet metal and pipe blanks in all dimensions at competitive prices. Simply upload CAD file and receive quote within 48 hours.

1.500+

Satisfied customers

5.500+

Available machines

0,11%

Complaint rate

Audited suppliers

Global network with over 500 audited suppliers

Attractive prices

Highest quality and competitive prices for all manufacturing processes

Fast delivery

With CNC24 you reduce your delivery time by up to 50%

Wide range of materials

All plastics and metals available in over 600 materials

Modern manufacturing with on-demand delivery

Precisely mastering the greatest complexity with laser cutting

CNC24 as an experienced online manufacturer offers all modern processes and methods of laser cutting. Whether in small or large series, as a single piece, prototype or even as a spare part – computer-controlled laser steel cutting of materials is a fast, precise and extremely economical CNC manufacturing method. Therefore, laser cutting of sheet metal and tubes is an integral part of CNC24’s manufacturing program.

Laser cutting

Technical data

| Traverse paths: | X-axis: up to 4,000 mm Y-axis: up to 2,000 mm | |

| Material thickness: | up to 50 mm | |

| Tolerances: | up to +/- 0.1 mm | |

| Batch sizes: | from 1 piece | |

| Best file formats: | STEP, PDF, DXF |

Our materials

Available materials

| Aluminum | Brass |

| Bronze | Nickel silver |

| Stainless steel | other materials on request |

| Steel | |

| Spring steel |

Upload

File formats

Briefly explained

How does laser cutting work?

In laser cutting, a workpiece is cut with a continuous or pulsed laser beam by so-called material ablation. A distinction is made between the three manufacturing processes, laser fusion cutting, laser flame cutting or laser sublimation cutting, which are used depending on the material thickness and product requirements.

Laser melt cutters continuously melt the material to be ablated at the cut edges and blow out the ablation material with a gas. Laser flame cutters burn the ablation material directly in the cut edges. Laser sublimation cutting vaporizes it right there.

CNC24 mainly uses CO2 lasers. Only when cutting temperature-sensitive material, such as copper or aluminum, do we use solid-state lasers that work with a neodymium-doped YAG crystal (Nd:YAG) in the near-infrared range.

Laser cutting is characterized by precise and sharp-edged material removal and is suitable for both small and large quantities.

Why CNC24

Your advantages

- Flexible and free capacities at any time

- Attractive prices for all components

- Quality control according to ISO 9001:2015

- One contract and contact person for all manufacturing processes

- Digital processes with personal contact person

- Global Supply Chain with German Quality Standards 🇩🇪

You have the choice

Our delivery times

- Offer within 48 hours

- Standard production in 15-20 working days

- Express service in 6-12 working days

Get a quote for your parts

We will send you a suitable offer within 48 hours

Laser cutting FAQs

Top laser cutting questions and answers

How does CNC24 laser cutting pricing compare to traditional methods?

CNC24 optimises costs by utilising advanced laser cutting technology, offering competitive pricing compared to traditional methods. Its efficiency and precision reduce waste and turnaround time, providing economical options for both large and small projects.

What design considerations should be taken into account for CNC24 laser cutting?

CNC24 requires designs to be in specific file formats with clear instructions on material, thickness and cut lines. We recommend optimizing designs for material efficiency and reviewing their minimum feature size guidelines to ensure quality results.

How does CNC24 protect design confidentiality?

CNC24 adheres to strict privacy policies to ensure the confidentiality of all customer designs. They use secure data transfer methods and have measures in place to protect intellectual property as outlined in their ISO 9001 certification standards.

What are CNC24’s environmental practices in laser cutting?

CNC24 is committed to sustainability, using energy efficient laser cutting technology and recycling materials wherever possible. Their ISO 9001 certification includes environmental impact considerations, ensuring that they strive to minimize their environmental footprint..

Have more questions?

Surface treatment

We get the best out of your components

Refinement, appearance, protection against wear and corrosion prophylaxis of the turned components are as much part of our core business as the production of components.

- Sandblasting

- Paint

- Anodizing

- Powder coating

- Electroless nickel

- Galvanizing

- Passivate

- Chromate

Your partner for all components

Other manufacturing processes

Experience you can build on

The CNC24 team combines over 30 years of experience in the production of precision components

500+

Finished

5.500+

Machines

80.000

Machine hours / Day

22

Countries

1.500+

Customers

6.000+

Orders

500.000

Individual parts

30 years

Manufacturing experience

Perfect components in just 3 steps!

1

Make a request

Upload production drawing and specify order. You will receive your offer within 48 hours.

2

Quality control

We find the right paver, supervise production and take care of quality control in our in-house measuring center.

3

Components received

You receive your quality-tested components including detailed test certificate.

Security and services

We make procurement simple

Non-Disclosure Agreements

IP protection is important to us. All partners are subject to strict non-disclosure agreements (NDA) to protect your intellectual property and keep your purchasing terms confidential.

Framework agreements

Secure attractive purchasing conditions and high quality in series production. Talk to us about framework agreements for stable prices with long-term supply.

One contractor

CNC24 is your sole contractual and contact partner throughout the entire project. We guarantee quality and on-time delivery for all orders.

CNC24

The easiest way to order components