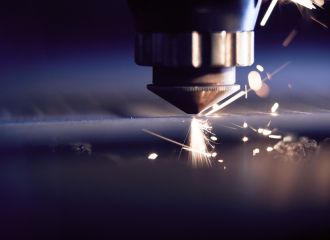

We process any metal

Machining at CNC24

- Your request in a few minute

- Offer within 48 hours

- Attractive prices and highest quality standards

1.500

Satisfied customers

5.500

Available machines

0,11%

Complaint rate

High precision machining services

Machining is the removal of material from a semi-finished product or preliminary product by cutting. Machining is used to produce a defined geometry, or to incorporate holes and recesses. In addition to the basic implementation of a machining operation, the greatest challenge in this machining process is maintaining the specified tolerances. Thanks to our modern and powerful machinery, we at CNC24 are able to implement customer specifications with particularly high precision and consistent quality.

Why CNC24

Your advantages

- Flexible and free capacities at any time

- Attractive prices for all components

- Quality control according to ISO 9001:2015

- One contract and contact person for all manufacturing processes

- Digital processes with personal contact person

- Global Supply Chain with German Quality Standards 🇩🇪

You have the choice

Our delivery times

- Offer within 48 hours

- Standard production in 15-20 working days

- Express service in 6-12 working days

Get a quote for your parts

We will send you a suitable offer within 48 hours

Briefly explained

Functionality of machining

In machining, a starting material is precisely removed by a radially or linearly guided tool. Semi-finished products such as sheets, blocks or profiles can be used as starting material.

In addition, products that have already been extensively machined can also be further upgraded through targeted machining. Machining is a central task area in metalworking. The manufacture of products with geometrically defined precision therefore requires the use of skilled labor.

At a glance

Machining processes at a glance

As a full-service provider, CNC24 offers you all non-cutting and cutting machining processes from a single source. The machining process includes the following processes:

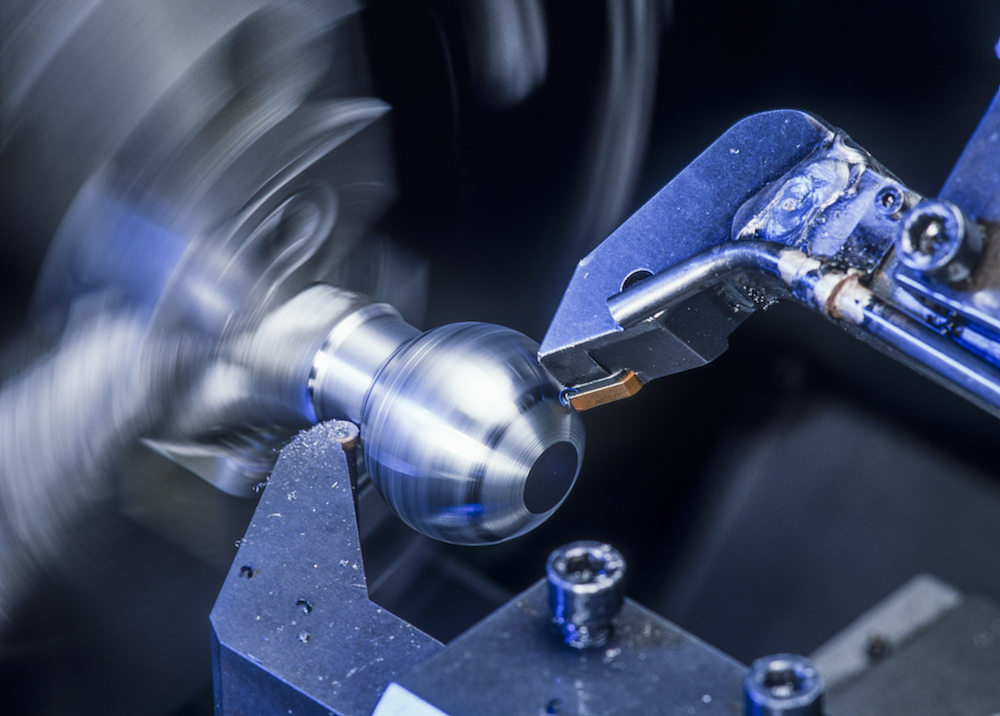

- CNC turning

- Saws

- Grinding

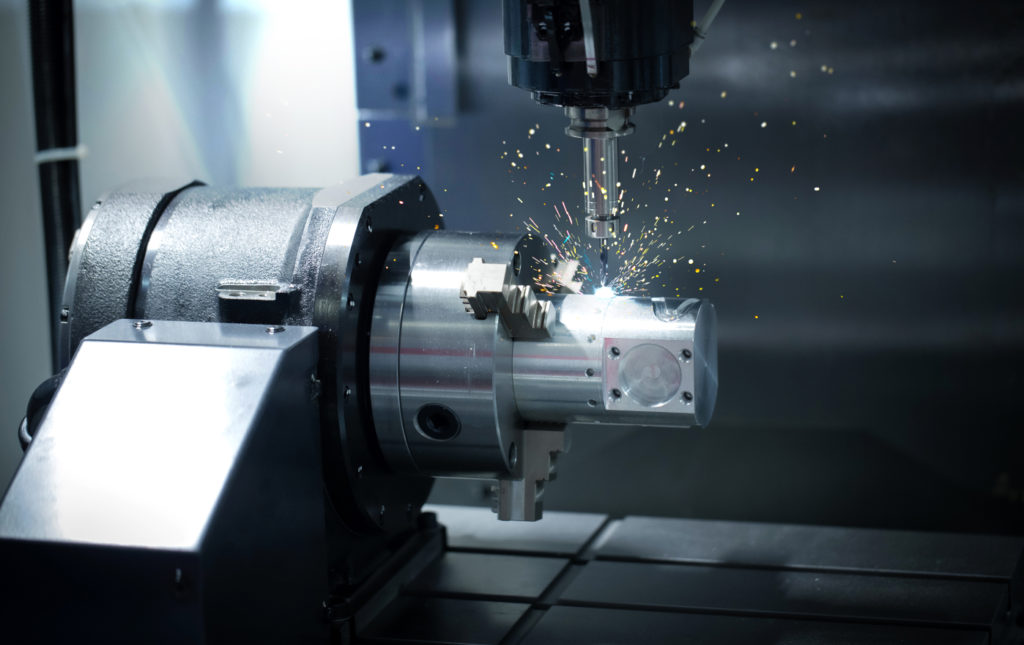

- CNC Milling

- Drilling

Get a quote for your parts

We will send you a suitable offer within 48 hours

Your advantages with small batch production

Outsourcing prototyping and small batch production has numerous advantages for your company:

- Relief of the own production

- Machining independent of material, dimensions, geometry or tolerances

- Fast delivery

- Consistent quality

- Interesting price-performance ratio

Turning is the production of rotationally symmetrical turned parts. The device used for turning is the lathe. Milling allows almost any geometry to be machined out of solid blocks. The design freedom is defined by the axes of the milling machine used, or “milling machine” for short. Saws cut a semi-finished product to a desired length. Sawing precedes turning or milling. It prepares the preliminary products in such a way that they fit into the processing machines.

Drilling is a process of making blind holes and through holes in a pre-product. These holes are further machined by reaming, countersinking or tapping. Grinding is the fine and final finishing of the workpiece. Grinding can be used to structure the surface or achieve the desired tolerance. The increases from the grinding are the lapping and the polishing.

In addition to conventional machining of workpieces, CNC machining is a common standard today. CNC machining enables a particularly precisely controlled manufacturing process for turning and milling. The programmed feed motion of the milling spindle or the cutting motion from the lathe tool makes series production of consistent quality possible.

Machining is not only a manufacturing process for small series and prototypes. Even in large-scale production, the various cutting machines are a standard part of the process chains. The use of preliminary products whose geometries are as close as possible to the final shape makes the use of the cutting machines particularly efficient.

Your partner for all components

Other manufacturing processes

Material overview

Materials for machining

In principle, all solid materials can be machined. The results are defined by the settings of the machines and the cutting tools. Even glass or ceramics can be machined into a desired shape using appropriately designed processes. The following materials are the most widely used in machining technology:

- Metal: especially steel, aluminum and non-ferrous metals

- Plastics

The machines we use can be used for numerous materials. This gives us maximum flexibility to handle your machining tasks.

Flexible application

Advantages of machining

The main advantage with the machining process is that it can be used to produce almost any geometry. Only completely enclosed cavities cannot be produced with it. Today, however, the innovative 3D printing processes are available for this purpose. Machining can also be used to achieve virtually any tolerances. When a turning or milling machine has reached the end of its manufacturable precision, the various grinding processes can remove the last thousandths of a millimeter to the required precision.

We at CNC24 are ready with our state-of-the-art machinery to implement your machining tasks. You define the shape and the tolerance, we manufacture the product according to your specifications. Use our online form or call us. Together we will find the best way to meet your machining challenges.

CNC24 is the leading portal for machining in Europe

CNC24 simplifies the procurement of CNC turned and milled parts.

CNC24 is your specialist and contact for prototypes, single parts, small series as well as for higher quantities. Our know-how in CNC turning and CNC milling, our own experience in manufacturing, a Europe-wide network of partners and the CNC24 quality management according to DIN EN ISO 9001:2015 make us your competent partner.

CNC24

The easiest way to order components